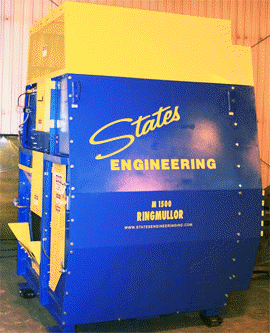

| States Engineering "M-1500 Ringmullor", with a

PLC Touch Screen Control Panel. |

| |

The installation of this unit will allow C&L to

add two additional sand molding lines and

increase its production by 40%. The M-1500 Ringmullor can discharge over sixteen tons of

uniformly prepared sand per hour, which in-turn

will reduce scrap rates, improve casting finish

and lower cleaning and grinding expenses.

C&L’s new Ringmullor measures the batch, cools the

sand before mulling, mulls, accurately controls

moisture content, power-aerates and discharges

uniformly prepared cool molding sand. Proper

mulling is fundamental to the production of

quality castings in green sand high production

environments.

Preparation of green molding sands

involves mixing sand, water, clay and carbon to

a consistent composition, and activating the

clay. |

| |

|

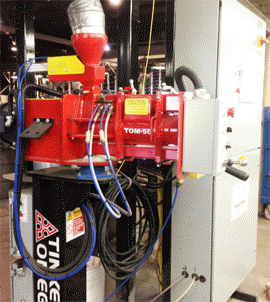

Tinker Omega

Manufacturing, "TOM-50" High Speed Continuous No

Bake Mixer, with a PLC Touch Screen Control

panel. |

| |

The addition of a Continuous No Bake Mixer

allows C&L a gateway in to the No Bake

Chemically Bonded Sand market. C&L can increase

its production efficiency, minimize waste and

reduce the need for skilled labor.

No Bake molding uses chemically bonded sand and

is used for castings that require intricate

detail and a smooth surface finish. No Bake

molding allows C&L to create a casting with high

mechanical properties and dimensional stability.

Additionally, complex core assemblies may be set

into the mold to create indicate parts with

stable dimensions. |

|

|

|

|

|

|

States Engineering "M-1500 Ringmullor" |

|

|

|

| |

Tinker Omega "TOM-50" High Speed

Continuous No Bake Mixer |

|